By: Nick Knotts, Industrial Engineer, The Lawton Standard Company

Damascus Steel Castings Co. merged into Temperform, LLC. as a product line in 2020. Prior to merging with Temperform, Damascus Steel had been servicing customers since 1906 in a variety of industries, though predominantly serving coal, scrap metal, construction, and seamless tubes. Damascus products are made from a variety of different materials, though the most common are low alloy steels, manganese steels, nickel-based alloys, and white irons. Damascus’ product base, particularly in low alloy steels and manganese steels, has allowed Temperform to largely expand its product offerings beyond its traditional mix of predominantly heat and wear-resistant parts in stainless steels and white irons.

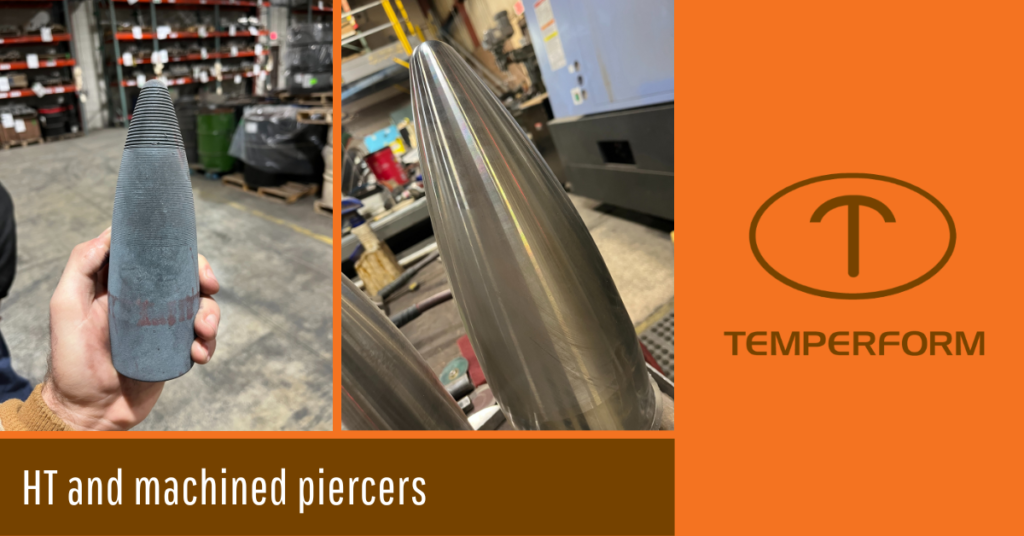

In terms of Damascus products, tooling for the seamless tube industry is among the most requested. Temperform makes a variety of products for all seamless tube needs, including piercer points, high mill plugs, reeler shoes, expander shoes and points, guide plugs, and more. Castings used for seamless tube piercing must be of high quality in order to handle the variety of different high stress environments in the seamless tube manufacturing process. An example is piercer points, which are some of the most highly critical castings to the seamless tube piercing process, they are responsible for the initial operation that hollows out the billet. The billet is fed over the piercing point around 2000 degrees Fahrenheit at a speed of around three feet per second. As a result, piercer points are made out materials that perform very well in terms of strength and toughness at elevated temperatures, particularly low alloy steels that are alloyed and heat treated to cater to higher temperature applications, and nickel-based super alloys.

An HT Piercer is a finished, machined, and heat-treated piercer point for seamless tube piercing made out of a low alloy steel. A machined piercer is a piercer point that is finished and machined, but has yet to go through its final heat treat cycle.

Other Damascus Steel products produced at Temperform include expander and reeler shoes. Expander/Reeler shoes are what the hollow rolls over during the expanding process while it is still at high temperature, thus, the shoes need to be able to resist creep and other stresses exhibited at high temperatures. To accommodate the working environment, these shoes are typically cast from heat resistant steels that are highly resistant to creep and oxidation. All the Damascus seamless tube products that are made by Temperform are made in a wide variety of sizes in order to best serve our customers.

A reeler shoe made out of ASTM HD.

Damascus’ offerings in the coal and scrap metal businesses are also commonly requested by customers. Predominately, these parts are utilized for crushing, such as hammers, breakers, and crusher blocks. These parts are almost always made from Austenitic (Hadfield) Manganese Steel, which is a material that has incredible toughness properties. Another unique property of manganese steel is that it will harden throughout service from around 240 BHN all the way up to 500 BHN or more when it is exposed to extensive amounts of wear and impact. In applications such as rock crushing, the ability of the material to harden throughout service makes it the best selection due to the large amount of wear that the parts experience in service. Rock crushing and breaking also involves a lot of blunt force impact, which is another area in which manganese steel excels as lasting.

A manganese steel splitting hammer that is used to crush rocks in mining applications.

Need castings from the Damascus product line? Need any steel castings? Reach out to Temperform and speak to a foundry expert today!